A. Radziszewski's „RESURS” private company

The company „RESURS” has existed since 1988 and widely known withCeconomic units both in Poland and abroad.

The technical term RESURS comes from French and means

experimentally and theoretically determined working period of an industrial object (a structure, a machine or a device), during the time that guarantees both exploitation performance and work safety.

The objective of our activity is determining the resurs of industrial objects (e.g. steel constructions, mechanical and powerplants devices) and considerable prolongation of their work.

This objective is realized by working in several main directions:

- technical diagnostics (evaluation of the technical condition) of machines and industrial devices:

- evaluation of the technical condition of steel constructions, including wolded joints;

- regenerative coatings and exploitation coatings (on parts of machines or devices)

sprayed by the following techniques:

— thermal spraying :

flame spray, arc spraying, HVOF spraying, plasma spraying;

— hardfacing welding :

gas welding penetration, electric arc welding;

— local regeneration of defects on the device at the Client's:

2 methods available: Nd:YAG laser micro-welding and brush plating coating;

— chemical nickel plating

including internal surfaces;

— ion nitriding.

- mechanical processing of parts measuring

1100 mm in diameter and 3000 mm in lenght

- non destructive testing (NDT) performed in cooperation

with „Energodiagnostyka Ltd.” company

- heat treatment of parts by means of magnetic methods MFT or CTT

TECHNICAL OFFER – since september 2012

In September 2012, we completed the project entitled „Increasing Competitiveness of the Company Resurs by Applying New Technologies in the field of Surface Engineering and Technical Diagnostics in Building and Exploitation of Industrial Appliances”, co-financed by the European Union from the European Regional Development Fund Regional Operational Programme of Mazovia in the yaers 2007 - 2013.

Introducing the new, expanded range of technical offer, which consists of:

diagnostic testing and defectoscopy testing letting to evaluate the level of stress and localisation of flaws (hidden defects) in the elements intended for repairing or regeneration. We apply the metal Magnetic Memory Method,

operating coating by thermal spraying, e.g. HVOF spraying or plasma spraying

turning components to 1100 mm in diameter and to 3000 mm in length on the lathe TR2-110x3M

grinding elements to 500 mm in diameter and 3000 mm in length on the grinder UB50/3000 CNC

We realize the above offer having in view environmental aspects. We have introduced a modern system of filters and ventilation in order to protect the natural environment from the particulates arising as a result of heat spraying.

The AP25i devices for plasma spraying

on regenerative coatings and exploitation coatings

Modern ventilation system

uses special filters to protect the environment

We also offer services and technical advice in the field of modern coatings replacing technical chrome.

TECHNICAL OFFER of the company „RESURS” – the range of services for industrial plants

Engineering of Metal Surfaces with regard to thermal spraying

( exploitation metallic coats, regeneration of metal losses )

and

Engineering of Metal Surfaces with regard to welding.

We also offer services and technical advice in the field of modern coatings replacing technical chrome.

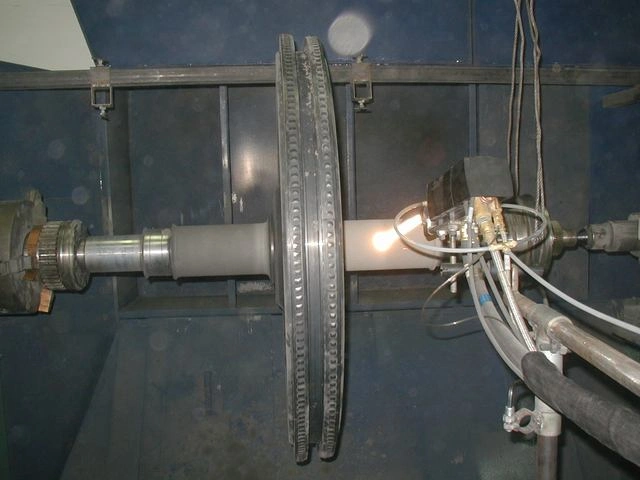

Regeneration of parts of large size:

thermal spraying and mechanical machining of long elements (up to 3 meters).

Repairs of parts of large size:

regeneration spigot with a diameter of 340mm on the shaft with 1600mm length of nicked pinion gears.

Control and measurement services:

performing the technical testing (NDT) of device and materials,

examination of the state of stress using Metal Magnetic Memory method (MMM method).

Exploitation of thermal sprayed coatings by HVOF process:

- wear-resistant coatings on the basis of carbides

(after the HVOF thermal spraying process coating will ground and polished).

The company „RESURS” offers services overhaul and repair of machines and devices such as:

- the technical expertise of status of devices by performing non-destructive testing and technical advice;

- the implementation and construction of new solutions, technical and economic analyzes, device upgrading;

- production or regeneration of parts for machinery, of equipment and means of transport;

- R&D work in the field of machinery technology.

TO SELL THE EQUIPMENT

The company „RESURS” also runs equipment sales:

- for diagnostics and for monitoring of industrial and constructions objects

- to application of metallic and non-metallic coatings.

Sale and service of measuring instruments

for the non-destructive testing of equipment and materials;

for magnetic diagnostics – Metal Magnetic Memory method (MMM method).

Sales and service of equipment (spray guns) and all the thermal spraying systems Metatherm companies.

We offer a wide range of materials used on the coatings.

Independently of sale of equipment we offer services in the area: thermal spray process.

Teaching Metal Magnetic Memory method (MMM method)

The company RESURS also organizes training in the range of:

thermal spraying, (spray metallization)

diagnostics devices by MMM method

Three presented photos show the specialists of the company „RESURS” and representatives of partner companies participating in trade fairs, exhibitions and trade conferences.

Cooperation

For many years we closely cooperate :

1. with the Russian company „Energodiagnostika” Co. Ltd.- Moskwa

testing for the application of mmM method, promoting mmM methods in Poland,

the sale of devices and the training of specialists.

We provide free consultations on of technical diagnostics by mmM method.

2. with the German company „Metatherm Flammspritztechnik” GmbH – Bexbach

in the promotion and sale of equipment for thermal spraying.

We provide free consultations in the range of thermal spraying techniques.

As part of the knowledge gained and experience of the company „RESURS” cooperates with companies and firms aiming to improve the quality of their products and services:

through the application of new technologies in the field of surface engineering;

through the application of new technologies in the field of surface engineering;

the company „RESURS” provides consulting services in the field of repair and diagnostics

the company „RESURS” provides consulting services in the field of repair and diagnostics

of devices designed to prevent accidents.

Invite you to cooperation - „RESURS” A. Radziszewski